Description

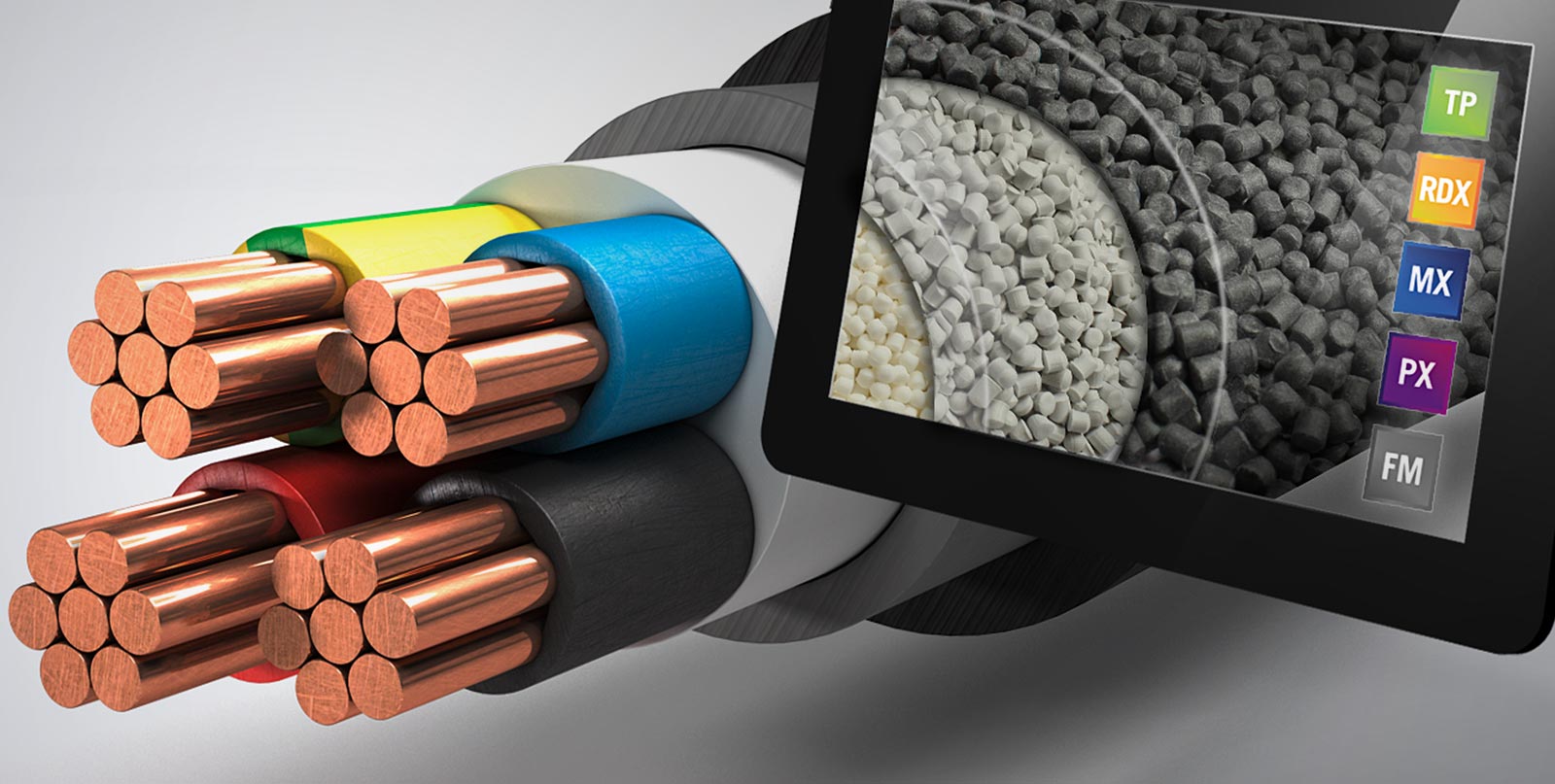

گرانول عایق افشان یکی از پرکاربردترین کامپاندهای مورد استفاده در صنعت سیم و کابل می باشد که طبق استاندارد IEC 60227 به نام PVC/D نامگذاری می شود. این محصول در گریدهای متفاوت و در انواع بی رنگ و رنگی تولید می شود.

گرانول عایق افشان در تولید کابل سبک افشان (کابل قابل انعطاف)،کابل قابل انعطاف سبک و معمولی، کابل کنترل افشان (NYSLY) و کابل کنترل افشان با هادی هم محور (NYSLYCY) در بازه ولتاژ ۵۰۰/۳۰۰ ولت، کابلهای تخت قابل انعطاف فشار متوسط، کابلهای بالابر و اتصالات متحرک تخت، مورد استفاده قرار می گیرد.

Reviews

There are no reviews yet.